Metering technology features of wired remote water meter

In the field of smart water services, Ningbo Jingcheng Technology Co., Ltd. has successfully developed a series of high-performance and high-reliability water meter products with its profound scientific research strength and innovative spirit. Among them, Wired Remote Water Meter has won wide acclaim in the market for its unique metering technology features.

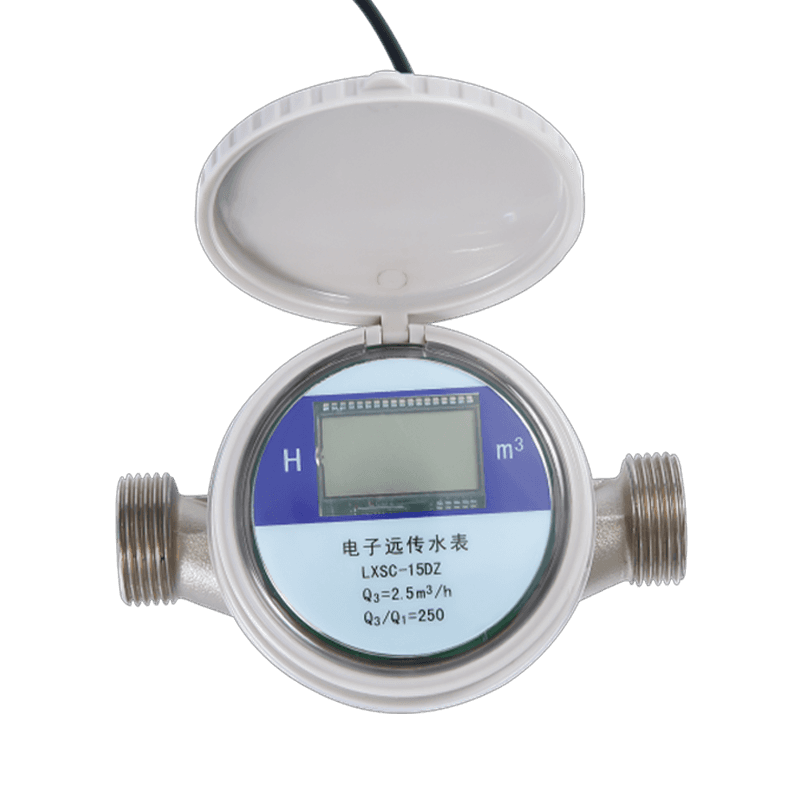

High-precision metering technology is a highlight of Wired Remote Water Meter. The water meter uses advanced flow sensors and high-precision metering chips to ensure the accuracy of the metering results. Its internal structure has been carefully designed to effectively reduce the water flow resistance, thereby improving the metering efficiency. Even in harsh operating environments, the water meter has shown excellent long-term stability and always maintains efficient metering performance. After strict comparison with international standards ISO 4064 B, C, and D, the metering error of Wired Remote Water Meter is controlled within an extremely low range, providing users with reliable water use data support.

In terms of flow detection technology, Wired Remote Water Meter also performs well. The water meter can accurately calculate the actual water consumption by real-time monitoring of key parameters such as water flow velocity and pressure, combined with advanced algorithm models. In addition, Wired Remote Water Meter has an intelligent recognition function, which can automatically distinguish flow changes in different water use scenarios, thereby providing more accurate metering results. The application of this technology enables users to obtain more scientific data support in water management.

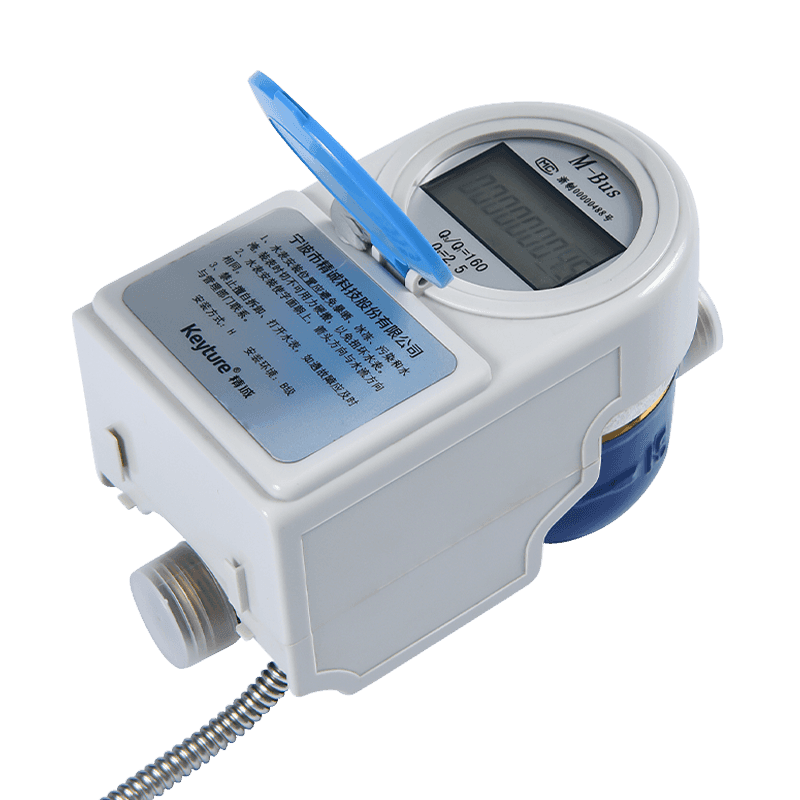

Remote monitoring and data transmission capabilities are another important feature of Wired Remote Water Meter. Through wired connection, the water meter realizes the function of uploading real-time data to the remote management system, and users can monitor and analyze metering data in real time. With the help of the remote management system, users can not only remotely open and close valves and set parameters, but also greatly improve management efficiency. In addition, the water meter supports a variety of communication protocols and interface standards, and can easily access various smart water management systems to achieve seamless data connection and sharing. This flexibility enables Wired Remote Water Meter to perform well in different application scenarios.

In terms of energy saving and environmental protection, Wired Remote Water Meter also demonstrates its excellent design concept. The water meter adopts a low-power design, which extends the service life of the equipment and reduces the impact on the environment. Its intelligent management function helps users optimize the water use structure and achieve the goal of water saving and emission reduction. By real-time monitoring and analysis of water use data, users can promptly identify and solve the problem of waste in the water use process, thereby further improving water conservation efficiency.

Benefits of Wired Remote Water Meters

The advantages of adopting a wired approach stem primarily from the system's inherent physical connection and power source:

- Exceptional Data Reliability and Stability: The fixed, physical connection provides a highly stable communication channel that is largely immune to radio frequency interference, signal blocking, and environmental noise, guaranteeing consistent data delivery.

- No Battery Dependency: Wired meters, particularly those using protocols like M-Bus, are often powered directly through the communication line. This eliminates the operational expense and maintenance task of periodic battery replacement.

- High Data Integrity: The controlled environment of a wired bus ensures lower latency and a more secure, less exposed data path, which is critical for accurate billing and regulatory compliance.

- Optimized for Dense Applications: Wired systems are ideal for high-density environments like apartment complexes, industrial parks, and multi-building campuses where the infrastructure can be installed centrally.

Types of Wired Remote Water Meters

Wired remote water meters are broadly categorized by the physical mechanism they use to measure water flow and the communication protocol they employ.

1. By Measurement Type:

- Pulse Output Meters: These are traditional mechanical meters retrofitted with a sensor that generates an electrical pulse for every unit of water consumed. They offer a simple, cost-effective way to get a digital reading but provide minimal diagnostic data.

- Direct-Reading Electronic Meters (Photoelectric): These advanced meters capture the actual meter reading directly from the mechanical register's number wheels using optical sensors, ensuring the remote reading is identical to the mechanical reading.

- Ultrasonic Meters: These meters use sound waves to measure the flow rate, offering high accuracy, no moving parts, and rich diagnostic data, typically communicating via a digital protocol like RS-485 or M-Bus.

2. By Communication Protocol:

The two most prevalent wired communication protocols in metering are:

- M-Bus (Meter-Bus): The European standard (EN 13757) specifically designed for reading utility meters (water, gas, heat, electricity). It uses a two-wire, non-polar connection, simplifies wiring, and can often power the meters from the bus.

- RS-485: A robust industrial electrical signaling standard that is often paired with the Modbus RTU (Remote Terminal Unit) application protocol. It is highly resistant to noise and supports multi-drop networks, making it common in industrial and commercial building management systems.

Applications of Wired Remote Water Meters

Wired remote water meters are essential components of Advanced Metering Infrastructure (AMI) systems, offering reliable, high-integrity data transmission for accurate billing, leak detection, and water management across diverse sectors.

- Residential: In multi-story buildings, apartment complexes, and gated communities, wired meters utilizing protocols like M-Bus (Meter-Bus) provide a highly stable and cost-effective solution for centralized meter reading. This eliminates the need for manual readings in individual units, ensuring precise, timely billing and quick detection of leaks within a housing block.

- Commercial: Retail centers, office buildings, and hotels use wired meters to accurately measure consumption for sub-metering tenants or to track water usage for billing optimization. The need for continuous, stable data in these environments favors the high reliability of protocols such as RS-485 Modbus RTU.

- Industrial: Manufacturing plants, food processing facilities, and power stations require extremely reliable and frequent data for process control, water quality monitoring, and cost allocation. Wired meters, especially those employing robust protocols, are preferred because they are less susceptible to the high electromagnetic interference often present in industrial settings. Ningbo Jingcheng Technology Co., Ltd., an established high-tech enterprise specializing in smart water meters, heat meters, and communication collection equipment, offers a range of wired remote water meter series, including those that use RS-485 and M-Bus communication, well-suited for high-demand industrial applications.

- Agricultural: While wireless is common for remote fields, wired systems are used in large, centralized irrigation pump stations and greenhouses where high data stability is critical for automated process control and regulating water usage for high-value crops.

- Municipal (District Metering Areas - DMAs): Water utilities use wired bulk meters at key points in the distribution network (DMAs) to measure flow, identify non-revenue water loss, and monitor pressure. The stability of wired communication is critical for ensuring the integrity of data used for critical network analysis.

Maintenance and Troubleshooting

Wired remote water meter systems are known for their low long-term maintenance needs, but like any electronic system, they require routine checks and can encounter specific issues.

Regular Maintenance Tasks

- Physical Inspection: Regularly check the meter body and the junction box for any signs of water ingress, corrosion, or physical damage.

- Cable Integrity Check: Visually inspect all wiring and cable sheaths for wear, cuts, or strain, particularly at connection points. The wiring is the primary vulnerability in a wired system.

- Master/Concentrator Unit Diagnostics: Check the data collector (Master/Concentrator) unit's logs for communication errors, timeout warnings, or power-related issues, which can indicate a problem with a specific meter or the communication bus.

- Power Supply Verification: For bus-powered systems like M-Bus, verify that the master unit is supplying the correct voltage and current to the bus to ensure all connected slave devices (meters) are operating correctly.

Common Issues and Solutions

| Common Issue | Cause | Troubleshooting Solution |

|---|---|---|

| No Communication | Wiring fault (cut/shorted cable, incorrect polarity). | Check for continuity and correct polarity, especially with non-polarity-immune systems like standard RS-485. |

| Intermittent Errors | High electromagnetic interference (EMI) or improper grounding | Ensure proper grounding and use shielded cables where they run near power lines. Check if terminating resistors are correctly installed on the RS-485 bus. |

| Single Meter Offline | Meter failure or incorrect address setting. | Verify the meter's power supply and check its unique primary or secondary communication address using a handheld master tool. |

| Slow Reading Speeds | Excessive number of devices or long bus length exceeding specifications. | For RS-485/Modbus, consider adding a repeater to extend the signal. For M-Bus, check the load calculation against the Master's capacity. |

Troubleshooting Tips

- Isolate the Fault: Start by checking the nearest connection point to the data collector. If the first meter on the bus is communicating, the fault is further downstream.

- Check Protocol Parameters: For RS-485/Modbus, ensure the baud rate, parity, and stop bits are correctly set on both the meter and the master.

- Address Discovery: M-Bus typically supports a "discover" function to scan for all connected slave meters, making it easier to find a meter with an unknown or incorrect address.

Wired vs. Wireless Water Meters

The choice between a wired and wireless smart meter involves a trade-off between installation cost/flexibility and long-term data reliability/stability.

Pros and Cons of Each Technology

| Feature | Wired Meters (e.g., M-Bus, RS-485) | Wireless Meters (e.g., LoRaWAN, NB-IoT) |

|---|---|---|

| Pros | High Reliability: Immune to radio interference. Ultra-Low Latency: Real-time control. Constant Power: No batteries, low long-term maintenance. Data Integrity: Highly stable, secure data path. | Low Installation Cost: No trenching/cabling labor. Flexibility: Easy to install in existing buildings (retrofits). Scalability: Easy to add new nodes to the network. Long Distance: Wide-area network capability. |

| Cons | High Installation Cost: Requires extensive cabling, conduit, and labor. Low Flexibility: Difficult and disruptive to expand or upgrade. Distance Limits: Bus length and node count are finite (though protocols like M-Bus can reach ≈2.4 km at low speeds). | Reliability Risk: Susceptible to radio interference, signal blockage (e.g., deep basement installs). Battery Life: Requires periodic battery replacement (adds to long-term OpEx). Latency: Can have higher latency (not ideal for real-time control). |

Factors to Consider When Choosing

| Factor | Wired Meter Preference | Wireless Meter Preference |

|---|---|---|

| Building Type | New construction, multi-story buildings, industrial plants (where infrastructure is planned). | Existing buildings (retrofits), historical sites, widely dispersed properties. |

| Environment | Areas with high electromagnetic interference (industrial) or physical barriers (deep underground). | Rural, remote, or urban areas where cellular/radio coverage is strong. |

| Data Requirement | Critical, real-time control or processes requiring guaranteed data integrity. | Standard daily/hourly meter reading for billing and basic leak detection. |

Parameter Comparisons (Wired M-Bus vs. Wired RS-485)

These two wired standards, frequently used by manufacturers like Ningbo Jingcheng Technology Co., Ltd. for their smart meter series, show distinct differences in their technical makeup:

| Parameter | Wired M-Bus (Meter-Bus) | Wired RS-485 (Modbus RTU) |

|---|---|---|

| Purpose | Designed specifically for utility metering (European Standard EN 13757). | General-purpose industrial automation protocol. |

| Wiring | Two-wire, non-polar (polarity-free), lower-cost twisted pair. | Two- or four-wire, requires correct polarity, often needs shielded cable. |

| Power | Can remotely power slave devices from the bus (low-power meters). | Requires a separate power supply for the meters. |

| Topology | Highly flexible (Star, Line, or Tree) – simplifies installation. | Typically Bus (Line) only, requires termination resistors. |

| Node Count | High (Up to to devices per master, depending on power). | Lower (Typically up to 32 devices per segment without repeaters). |

| Ease of Configuration | Supports secondary addressing and device discovery, simplifying remote setup. | Relies on pre-programmed or manually set primary addresses. |

Cost Analysis

- Wired System (High CapEx, Low OpEx): Initial Cost (CapEx) is high due to the significant labor and material costs associated with laying cables, conduits, and junction boxes for every meter. However, Operational Cost (OpEx) is very low long-term because there are no batteries to replace, and troubleshooting is often simpler due to the physical connection's stability.

- Wireless System (Low CapEx, Higher OpEx): Initial Cost (CapEx) is low as there's minimal to no wiring. However, Operational Cost (OpEx) is higher over the system's lifespan due to the need for periodic battery replacement and potential expenses for maintaining a wireless network infrastructure (gateways, signal boosters, cellular data plans, etc.).

Long-Term Reliability

The long-term reliability of a wired system is generally superior for critical data collection because its performance is not dependent on environmental factors like radio frequency interference, physical obstructions (metal cabinets, thick walls), or battery life. Wireless systems offer flexibility, but their long-term reliability is subject to ongoing factors that a wired system largely eliminates.