KM06-04

Dry type magnetic drive wire remote, it is easy to disassemble and replace the measuring mechanism, large flow capacity, low-pressure loss and stable performance curve.

Description

1. Application

Measuring, memorizing, and displaying the volume of cold(hot) water passing through the pipeline.

2. Features

Corrosion Resistance: All the materials selected by resistance to corrosion;

Measuring Mechanism: Interchangeable, removable and can be easy removed from the body for checking, maintaining and replacing;

Directly Reading: The ROTATING indicator registers for the comfortable reading position;

Reliability: The copper can super dry register with lP68 protection for reliability;

Free Installation: Suitable for any position installation including Horizontal, Vertical and inclined;

High Performance: Low-pressure loss; No affected by external magnetic fields;

3. Main Technical Data

Water meter temperature grade: T30,T50,T70,T90

Pressure grade: MAP10

Pressure loss grade: △P63

Upstream disturbance grade: U10

Downstream disturbance grade: D5

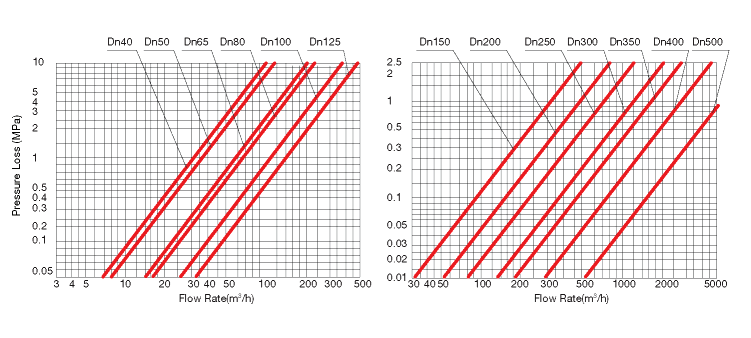

4. Head Loss Curve

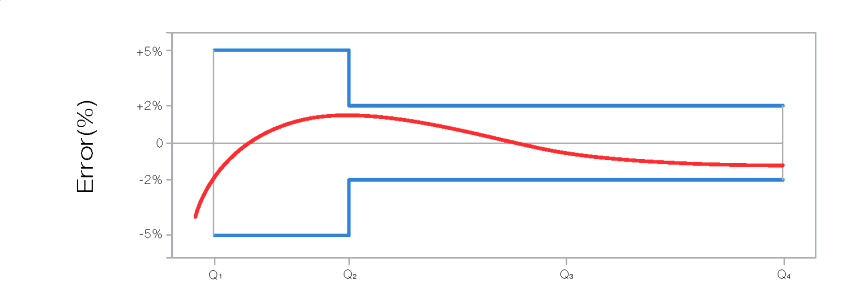

5. Max Permission Error

From Q1 inclusive up to but excluding Q2 is ± 5%;

From Q2 inclusive up to and including Q4 is ± 2% for T30 and + 3% for T50;

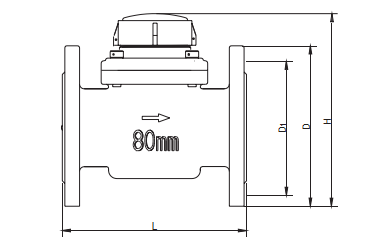

6. Installation Dimension

|

Diameter mm |

L |

D |

D1 |

H |

Connection flange |

|

mm |

Dxn |

||||

|

40 |

200 |

150 |

|

206 |

4XΦ19 |

|

50 |

200 |

165 |

125 |

210 |

4XΦ19 |

|

65 |

200 |

185 |

145 |

218 |

4XΦ19 |

|

80 |

225 |

200 |

160 |

280 |

4XΦ19 |

|

100 |

250 |

220 |

180 |

290 |

8XΦ19 |

|

125 |

250 |

250 |

|

310 |

8XΦ19 |

|

150 |

300 |

285 |

240 |

320 |

8XΦ23 |

|

200 |

350 |

340 |

295 |

364 |

8XΦ23 |

|

Bus power supply |

Work current |

Communication interface |

External power supply |

|

DC6.5V-18V |

≤5mA |

RS-485/MBUS |

RS-485:5-18V/MBUS:24-36V |

7. Installation

● It can be installed in any position including horizontal, Vertical and inclined with the direction of the flow as indicated by the arrow cast in the meter body.

● It needs to have 10 diameters straight pipe the head of the meter and 5 diameters straight pipe after to ensure proper flow through the meter.

● Straight pipe after to ensure proper flow through the meter.

● Pipeline must be flushed before installation.

● The meter should be constantly full of water during operation.

● We suggest you install the filter before the after-water meter.

In the water supply industry, the Mechanic Water Meter is widely utilized for its robust design and independence from external power sources. However,...

In the advancement of smart water infrastructure, NB-IoT (Narrowband Internet of Things) prepaid water meters have become the industry standard. Howev...

In the rapidly evolving landscape of Smart Water Management, selecting the appropriate metering technology is a critical decision for utility companie...

With the increasing importance of energy management, heat measurement has become a crucial aspect of heating systems. Traditional methods of heat meas...