KM06-03

Register may rotate more than 360 degree for easily reading in any position; application in commercial, institutional place.

Description

1. Application

Measuring , memorizing and displaying the volume of cold(hot) water passing through the pipeline.

2. Feature

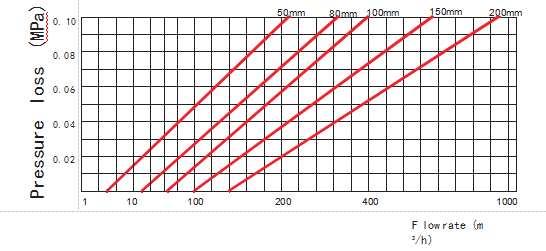

● Large flow capacity and small pressure lose.

● Anti-pollution , Built-in stainless steel strainer can save the installation cost. The measuring mechanism can be removable from the body for checking maintaining and replacing.

● Selected high-quality materials for steady and reliable characteristics.

● Vacuum sealed register ensures the dial kept from fog and keep reading clear in long-term service.

3. Main Technical Data

Water meter temperature grade: T30,T50,T70,T90

Pressure grade: MAP10

Pressure loss grade: △P63

Upstream disturbance grade: U10

Downstream disturbance grade: D5

Installation: Horizontally

No need additional filter

No requirement of straight pipe at inlet and outlet

4. Head Loss Curve

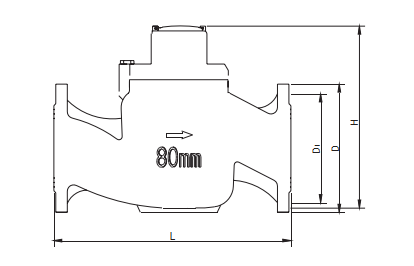

5. Installation Dimension

|

Diameter mm |

L |

D |

D1 |

H |

Connection flange |

Weight |

|

mm |

Dxn |

kg |

||||

|

40 |

245 |

|

|

220 |

|

7 |

|

50 |

280 |

165 |

125 |

228 |

4XΦ19 |

15 |

|

65 |

300 |

185 |

145 |

238 |

4XΦ19 |

16.8 |

|

80 |

370 |

200 |

160 |

290 |

4XΦ19 |

29 |

|

100 |

370 |

220 |

180 |

306 |

8XΦ19 |

31 |

|

150 |

500 |

285 |

240 |

445 |

8XΦ23 |

78 |

|

200 |

500 |

340 |

295 |

564 |

8XΦ23 |

120 |

6. Technical Data

|

Bus power supply |

Work current |

Communication interface |

External power supply |

|

DC6.5V-18V |

≤5mA |

RS-485/MBUS |

RS-485:5-18V/MBUS:24-36V |

7. Paramenters

| Model No. | DN(mm) | Flow range | Q4 | Q3 | Q2 | Q1 | Min. reading | Max. reading | |

| Q3/Q1 | Q2/Q1 | m3/h | m3 | ||||||

| WS-40 | 40 | 50 | 1.6 | 40 | 50 | 1.28 | 0.8 | 0.0005 | 999999 |

| 200 | 6.3 | 1.25 | 0.2 | 0.0005 | 999999 | ||||

| WS-50 | 50 | 50 | 1.6 | 40 | 50 | 1.28 | 0.8 | 0.0005 | 999999 |

| 200 | 6.3 | 1.25 | 0.2 | 0.0005 | 999999 | ||||

| WS-80 | 80 | 50 | 1.6 | 63 | 80 | 2 | 1.26 | 0.0005 | 999999 |

| 200 | 6.3 | 2 | 0.32 | 0.0005 | 999999 | ||||

| WS-100 | 100 | 50 | 1.6 | 100 | 125 | 3.2 | 2 | 0.0005 | 999999 |

| 200 | 6.3 | 3.12 | 0.5 | 0.0005 | 999999 | ||||

| WS-150 | 150 | 50 | 1.6 | 250 | 312 | 8 | 5 | 0.0005 | 999999 |

| 200 | 6.3 | 7.88 | 1.25 | 0.0005 | 999999 | ||||

| WS-200 | 200 | 50 | 1.6 | 400 | 500 | 12.8 | 8 | 0.0005 | 999999 |

| 200 | 6.3 | 12.5 | 2.5 | 0.0005 | 999999 | ||||

In the water supply industry, the Mechanic Water Meter is widely utilized for its robust design and independence from external power sources. However,...

In the advancement of smart water infrastructure, NB-IoT (Narrowband Internet of Things) prepaid water meters have become the industry standard. Howev...

In the rapidly evolving landscape of Smart Water Management, selecting the appropriate metering technology is a critical decision for utility companie...

With the increasing importance of energy management, heat measurement has become a crucial aspect of heating systems. Traditional methods of heat meas...