KM10-02

Ultrasonic remote water meter is a combined flow sensor with a microprocessor and adopts advanced ultrasonic measurement technology for measuring water consumption.

Description

1. Features

2. Working Condition

Water temperature≤50℃ for cold water; hot water meter ≤90℃.

Water pressure≤1MPa(PN:1.6MPa/16bar)

3. Electronic Parameter

| Temperature sensor pairing error | Low current protection | Working temperature | Static current | Rated operational voltage | Operating Voltage |

| <0.05℃ | <2.5V | 0.1~55℃ | <8uA | 3.6V | 2.5V-3.6V |

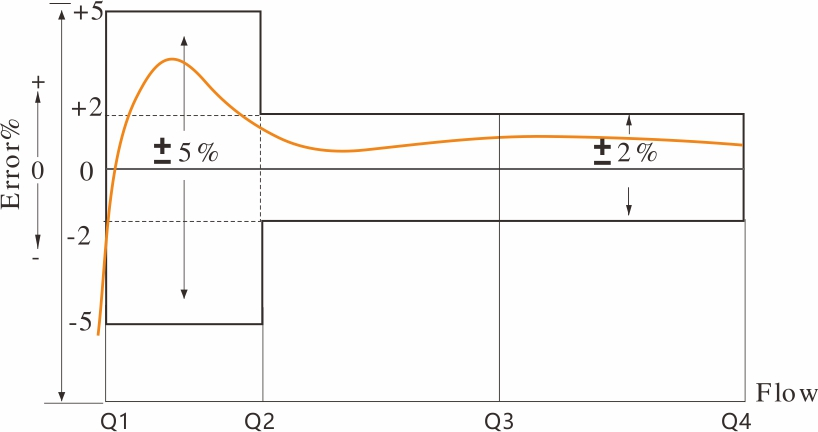

4. Accuracy Error Curve

5. Main Technical Data

| Nominal Diameter (DN) |

Q3/Q1 | Q4 m³/h | Q3 m³/h | Q2 m³/h | Q1 m³/h | Resolution of the indicating device [m³] |

Indicating range[m³] |

| 32 mm | R80 | 12.5 | 10 | 200 | 125 | 0.00001 | 99999.99 |

| R100 | 160 | 100 | |||||

| R160 | 100 | 62.5 | |||||

| 40 mm | R80 | 20 | 16 | 320 | 200 | ||

| R100 | 256 | 160 | |||||

| R160 | 160 | 100 | |||||

| 50 mm | R80 | 31.25 | 25 | 500 | 312.5 | ||

| R160 | 250 | 156.25 | |||||

| R200 | 200 | 125 | |||||

| 65 mm | R80 | 50 | 40 | 800 | 500 | ||

| R160 | 400 | 250 | |||||

| R200 | 320 | 200 | |||||

| 80 mm | R80 | 78.75 | 63 | 1250 | 787.5 | ||

| R160 | 625 | 393.75 | |||||

| R200 | 504 | 315 | |||||

| 100 mm | R80 | 125 | 100 | 2000 | 1250 | ||

| R160 | 1000 | 625 | |||||

| R200 | 800 | 500 | |||||

| 125 mm | R80 | 200 | 160 | 3200 | 2000 | ||

| R160 | 1600 | 1000 | |||||

| R200 | 1280 | 800 | |||||

| 150 mm | R80 | 312.5 | 250 | 5000 | 3125 | ||

| R160 | 2500 | 1562.5 | |||||

| R200 | 2000 | 1250 | |||||

| 200 mm | R80 | 500 | 400 | 8000 | 5000 | ||

| R160 | 4000 | 2500 | |||||

| R200 | 3000 | 2000 | |||||

| 250 mm | R80 | 787.5 | 630 | 12600 | 7875 | ||

| R160 | 5300 | 3937.5 | |||||

| R200 | 5040 | 3150 | |||||

| 300 mm | R80 | 1250 | 1000 | 20000 | 12500 | ||

| R160 | 10000 | 6250 | |||||

| R200 | 8000 | 5000 |

In the water supply industry, the Mechanic Water Meter is widely utilized for its robust design and independence from external power sources. However,...

In the advancement of smart water infrastructure, NB-IoT (Narrowband Internet of Things) prepaid water meters have become the industry standard. Howev...

In the rapidly evolving landscape of Smart Water Management, selecting the appropriate metering technology is a critical decision for utility companie...

With the increasing importance of energy management, heat measurement has become a crucial aspect of heating systems. Traditional methods of heat meas...