KM10-01

Ultrasonic remote water meter is a combined flow sensor with a microprocessor, and adopts advanced ultrasonic measurement technology for measuring water consumption. Step charging, abnormal alarm, battery easy to replace, automatic meter reading, Accurate billing, water data analysis and processing, leakage analysis.

Description

1. Features

2. Working Condition

Water temperature≤50℃ for cold water; hot water meter ≤90℃.

Water pressure≤1MPa(PN:1.6MPa/16bar)

3. Electronic Parameter

| Temperature sensor pairing error | Low current protection | Working temperature | Static current | Rated operational voltage | Operating Voltage |

| <0.05℃ | <2.5V | 0.1~55℃ | <8uA | 3.6V | 2.5V-3.6V |

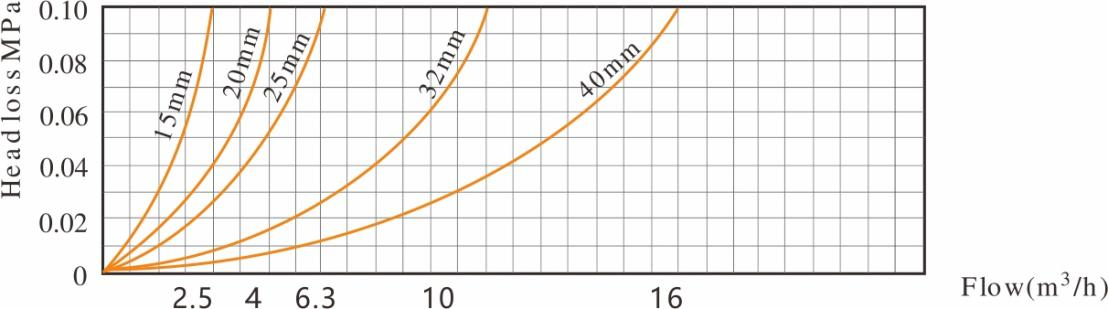

4. Head Loss Curve

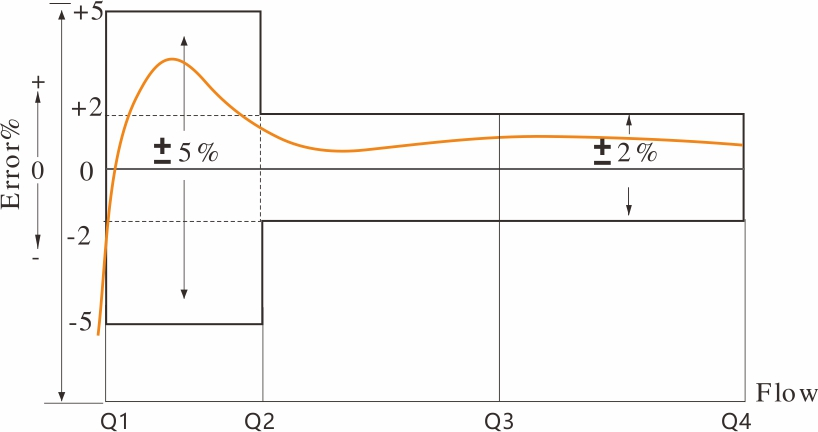

5. Accuracy Error Curve

6. Installation Dimension

| Item No | 20 | 25 | 32 | |

| L1 | mm | 130 | 160 | 180 |

| L | mm | 230 | 270 | 295 |

| H | mm | 100 | 105 | 110 |

| W | mm | 100 | 100 | 100 |

| Connection Thread | mm | G1 | G1-1/4 | G1-1/2 |

| Weight | kg | 0.7 | 0.9 | 1.2 |

7. Main Technical Data

| Nominal diameter (DN) |

8mm | 15mm | 20mm | 25mm | |

| Q4m³/h | 1.25 | 3.125 | 5 | 7.875 | |

| Q3 m³/h | 1 | 2.5 | 4 | 6.3 | |

| Q2m³/h | R80 | / | 50 | 80 | 126 |

| R100 | / | 40 | 64 | 100.8 | |

| R160 | 10 | 25 | 40 | 63 | |

| Q1m³/h | R80 | / | 31.25 | 50 | 78.75 |

| R100 | / | 25 | 40 | 63 | |

| R160 | 6.25 | 15.625 | 25 | 39.375 | |

| Resolution of the indicating device [m³] |

0.00001 | ||||

| Indicating range[m³] | 99999.9999 | ||||

| Nominal Diameter (DN) |

Q3/Q1 | Q4 m³/h | Q3 m³/h | Q2 m³/h | Q1 m³/h | Resolution of the indicating device [m³] | Indicating range[m³] |

| 32 mm | R80 | 12.5 | 10 | 200 | 125 | 0.00001 | 99999.99 |

| R100 | 160 | 100 | |||||

| R160 | 100 | 62.5 | |||||

| 40 mm | R80 | 20 | 16 | 320 | 200 | ||

| R100 | 256 | 160 | |||||

| R160 | 160 | 100 | |||||

| 50 mm | R80 | 31.25 | 25 | 500 | 312.5 | ||

| R160 | 250 | 156.25 | |||||

| R200 | 200 | 125 | |||||

| 65 mm | R80 | 50 | 40 | 800 | 500 | ||

| R160 | 400 | 250 | |||||

| R200 | 320 | 200 | |||||

| 80 mm | R80 | 78.75 | 63 | 1250 | 787.5 | ||

| R160 | 625 | 393.75 | |||||

| R200 | 504 | 315 | |||||

| 100 mm | R80 | 125 | 100 | 2000 | 1250 | ||

| R160 | 1000 | 625 | |||||

| R200 | 800 | 500 | |||||

| 125 mm | R80 | 200 | 160 | 3200 | 2000 | ||

| R160 | 1600 | 1000 | |||||

| R200 | 1280 | 800 | |||||

| 150 mm | R80 | 312.5 | 250 | 5000 | 3125 | ||

| R160 | 2500 | 1562.5 | |||||

| R200 | 2000 | 1250 | |||||

| 200 mm | R80 | 500 | 400 | 8000 | 5000 | ||

| R160 | 4000 | 2500 | |||||

| R200 | 3000 | 2000 | |||||

| 250 mm | R80 | 787.5 | 630 | 12600 | 7875 | ||

| R160 | 5300 | 3937.5 | |||||

| R200 | 5040 | 3150 | |||||

| 300 mm | R80 | 1250 | 1000 | 20000 | 12500 | ||

| R160 | 10000 | 6250 | |||||

| R200 | 8000 | 5000 |

In the water supply industry, the Mechanic Water Meter is widely utilized for its robust design and independence from external power sources. However,...

In the advancement of smart water infrastructure, NB-IoT (Narrowband Internet of Things) prepaid water meters have become the industry standard. Howev...

In the rapidly evolving landscape of Smart Water Management, selecting the appropriate metering technology is a critical decision for utility companie...

With the increasing importance of energy management, heat measurement has become a crucial aspect of heating systems. Traditional methods of heat meas...