KM07-04

Ultrasonic remote water meter is a combined flow sensor with a microprocessor and adopts advanced ultrasonic measurement technology for precise and reliable measuring the water consumption for commercial and industrial applications. Long service life, complete output communication functions, to meet all kinds of communication and wireless networking requirements, with small flow detection capabilities.

Description

1. Features

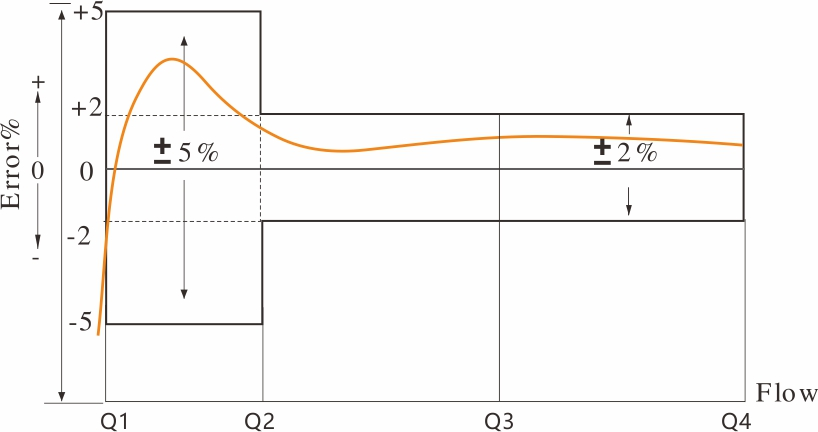

2. Technical Condition

| Maximum permissible error for the | ±5% |

| Lower flow rate zone (MPEι) | |

| Maximum permissible error for | ±2% for water having a temperature ≤30℃ |

| The upper flow rate zone (MPEμ) | ±3% for water having a temperature >30℃ |

| Temperature class | T30,T50,T70 |

| Water pressure classes | MAP 16 |

| Pressure-loss classes | △P10 |

| Indicating range[m³] | 99 999 |

| Resolution of the | 0.00005 |

| Indicating device[m³] | |

| Flow profile sensitivity classes | U10 D5 |

| Orientation limitation | HORIZONTAL |

3. Electronic Parameter

| Power supply | Communication Interface | Communication Protocol |

| 3.6V (24VDC 220VAC) | M-BUS, RS485(4-20mA), WM-BUS, LORA, NB-IoT | GB/T 26831, CJ/T188, MODBUS RTU |

4. Accuracy Error Curve

5.Installation Dimension

| Item No | 50 | 80 | 100 | 150 | 200 | |

| L | mm | 200 | 200 | 250 | 300 | 350 |

| H | mm | 390 | 420 | 440 | 495 | 555 |

| D | mm | 165 | 200 | 220 | 285 | 340 |

| nXφD1 | mm | 4Xφ18 | 8Xφ18 | 8Xφ18 | 8Xφ22 | 12Xφ22 |

6. Main Technical Data

| Nominal | Starting flow | Q3/Q1 | Q2/Q1 | Q4 m³/h | Q3 m³/h | Q2 m³/h | Q1 m³/h |

| Diameter (DN) | |||||||

| 50 | 0.035 | 100 | 1.6 | 78.75 | 63 | 1.008 | 0.63 |

| 65 | 0.06 | 100 | 1.6 | 125 | 100 | 1.6 | 1 |

| 80 | 0.09 | 100 | 1.6 | 200 | 160 | 2.56 | 1.6 |

| 100 | 0.141 | 160 | 1.6 | 312.5 | 250 | 2.501 | 1.563 |

| 125 | 0.221 | 160 | 1.6 | 312.5 | 250 | 2.501 | 1.563 |

| 150 | 0.318 | 160 | 1.6 | 500 | 400 | 4 | 2.5 |

| 200 | 0.565 | 160 | 1.6 | 787.5 | 630 | 6.301 | 3.938 |

| 250 | 0.883 | 160 | 1.6 | 1250 | 1000 | 10 | 6.25 |

| 300 | 1.27 | 160 | 1.6 | 2000 | 1600 | 16 | 10 |

In the sector of industrial water supply and metering, the Large-diameter Mechanic Water Meter has historically held a dominant position. However, wit...

In the water supply industry, the Mechanic Water Meter is widely utilized for its robust design and independence from external power sources. However,...

In the advancement of smart water infrastructure, NB-IoT (Narrowband Internet of Things) prepaid water meters have become the industry standard. Howev...

In the rapidly evolving landscape of Smart Water Management, selecting the appropriate metering technology is a critical decision for utility companie...