Water meters are essential tools for measuring the volume of water consumed by residential, commercial, and industrial users. They are fundamental to accurate billing, effective resource management, and the early detection of leaks. For decades, the industry standard has been the mechanical water meter, a technology that relies on moving parts to measure flow.

However, the advent of digital technology has introduced a new player: the ultrasonic water meter. This advanced device uses sound waves to measure water usage, offering a fundamentally different approach. The choice between these two types of meters has significant implications for accuracy, longevity, cost, and overall utility management. This article provides a comprehensive comparison to help you understand the key differences and determine which type is the best fit for your specific needs.

Mechanical water meters, also known as traditional or analog meters, rely on a physical mechanism to measure the volume of water flowing through them. This technology has been a cornerstone of water utility management for over a century due to its simplicity and reliability. There are two primary types of mechanical meters, each with a different operational principle:

1. Positive Displacement Meters

These meters measure water by trapping and counting a fixed volume of water with each cycle of a moving component. They are highly accurate, particularly at low flow rates, and are a common choice for residential applications.

Working Principle: As water enters the meter, it causes a chamber or piston to move. This motion is directly proportional to the volume of water that has passed. For example, a nutating disc meter has a disc that wobbles as water flows, with each complete wobble representing a set volume. This mechanical movement is then transferred via a magnetic coupling to a register that displays the total volume.

Best For: Low to medium flow rates, residential and small commercial use, and applications requiring high accuracy at low flows.

2. Velocity Meters

Velocity meters measure the speed of the water flow to calculate the total volume. They are typically used for larger pipes and higher flow rates, where a positive displacement meter might be too restrictive.

Working Principle: Water flows through a chamber containing a turbine, impeller, or propeller. The water's velocity causes this component to rotate at a speed directly proportional to the flow rate. A gear train or magnetic coupling then transmits the rotation to a register that converts the rotational speed into a total volume.

Best For: High flow rates, large commercial and industrial applications, fire services, and main distribution lines.

Parameter Comparison

| Parameter | Positive Displacement Meters | Velocity Meters |

| Measurement Principle | Counts fixed volumes of water | Measures water velocity |

| Accuracy | High at low flow rates | Good at high flow rates |

| Flow Rate | Best for low to medium flows | Best for high flows |

| Internal Mechanism | Nutating disc, oscillating piston | Turbine, impeller, propeller |

| Typical Application | Residential, small businesses | Commercial, industrial, main lines |

Advantages of Mechanical Water Meters

Cost-effectiveness: Mechanical meters generally have a lower initial purchase price compared to their ultrasonic counterparts. This makes them an attractive option for large-scale deployments where budget is a primary concern.

Simplicity and ease of maintenance: With a straightforward design, mechanical meters are easy to install, operate, and maintain. Their technology is well-understood, and replacement parts are readily available.

Established technology: Mechanical meters have been in use for over a century. Their reliability and performance are proven, and they meet industry standards worldwide.

Disadvantages of Mechanical Water Meters

Susceptibility to wear and tear: Because they contain moving parts, mechanical meters are prone to wear and tear over time. This can lead to decreased accuracy and a shorter lifespan, particularly when dealing with abrasive materials in the water.

Potential for inaccuracies due to debris: Sediment, sand, and other debris in the water can interfere with the moving parts, causing the meter to slow down, get stuck, or provide inaccurate readings.

Limited flow range: Mechanical meters have a relatively limited flow range. While they can be accurate at either low or high flow rates depending on their design, they may not perform well across a wide range of flows.

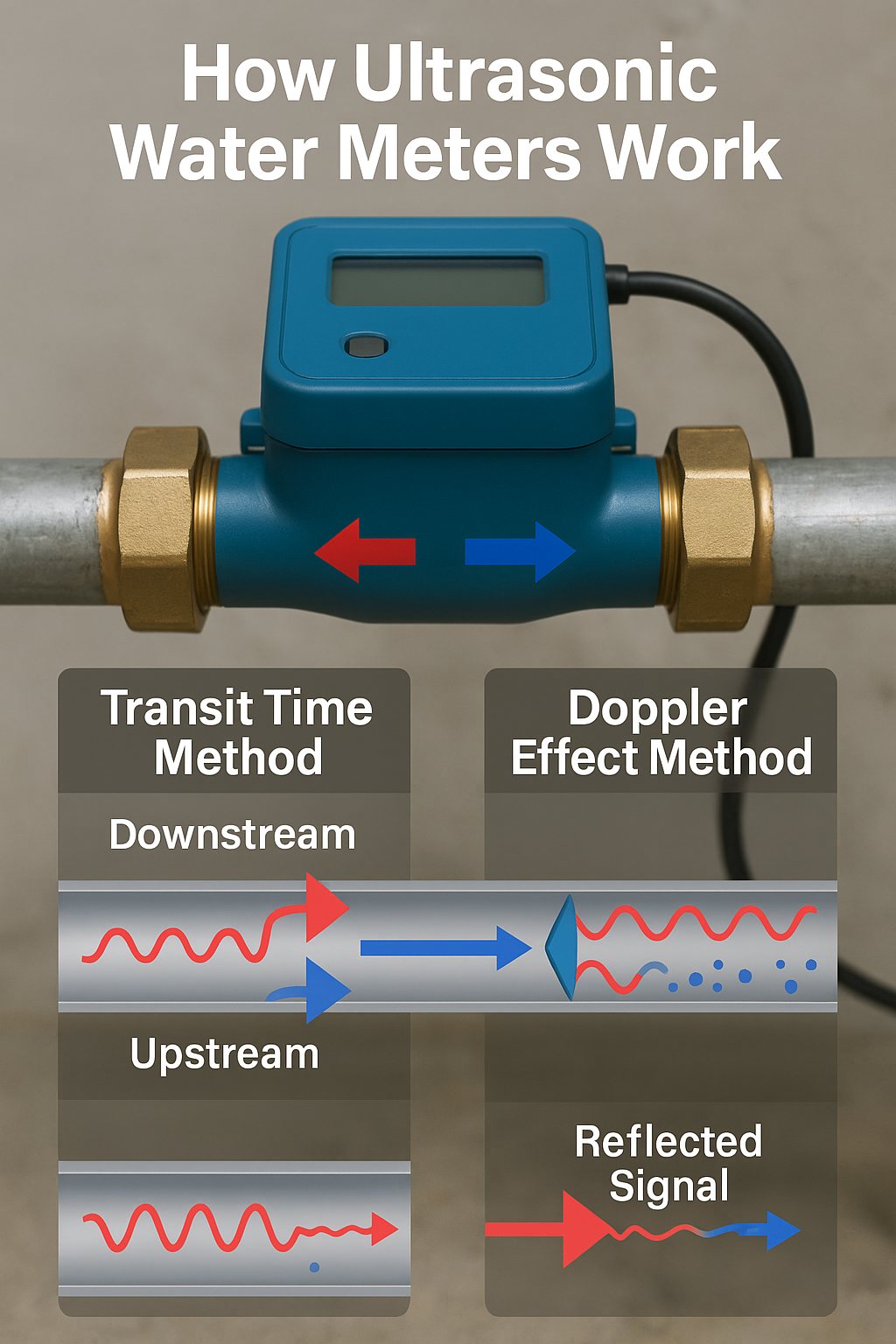

Ultrasonic water meters use sound waves to measure the flow rate of water without any moving mechanical parts. This technology provides high accuracy and durability, as it's not affected by wear and tear or debris. There are two primary methods used in these meters:

1. Transit Time Method

This is the most common method for measuring clean, homogeneous liquids like tap water. It relies on the principle that sound travels faster when moving with the flow of water and slower when moving against it.

Working Principle: The meter contains two transducers (a pair of sensors) placed on opposite sides of the pipe. One transducer sends an ultrasonic pulse (a high-frequency sound wave) downstream with the flow, while the other simultaneously sends a pulse upstream against the flow. The time it takes for each pulse to reach the opposite transducer is precisely measured. The difference between the upstream and downstream travel times is directly proportional to the velocity of the water. The meter's electronics use this velocity and the known pipe dimensions to calculate the total volume of water that has passed through.

Best For: Clean water applications, residential and commercial billing, and scenarios where high accuracy at very low flow rates is crucial.

2. Doppler Effect Method

This method is used for liquids that contain suspended particles or air bubbles, such as wastewater or slurries.

Working Principle: A single transducer sends a continuous ultrasonic signal into the flowing fluid. As the fluid moves, the sound waves reflect off the moving particles or bubbles within the stream. Due to the Doppler effect, the frequency of the reflected signal changes. This frequency shift is directly proportional to the velocity of the particles, which in turn reflects the velocity of the fluid itself. The meter then calculates the flow rate based on this frequency shift.

Best For: "Dirty" water applications, industrial processes, and any flow where the fluid is not perfectly clean.

Advantages of Ultrasonic Water Meters

High accuracy and reliability: Without any moving parts to wear down, ultrasonic meters maintain their initial high accuracy over their entire lifespan. They are particularly effective at detecting very low flow rates, which is crucial for identifying small leaks.

Wide flow range: These meters can accurately measure flow from a trickle to a powerful stream, making them suitable for a diverse range of applications.

No moving parts: The absence of mechanical components eliminates friction, wear, and potential blockage from sediment, significantly reducing maintenance needs.

Advanced features: Many ultrasonic meters are "smart" meters with built-in electronics that can provide real-time data, leak alarms, and remote reading capabilities, making them a key component of a modern water management system.

Disadvantages of Ultrasonic Water Meters

Higher initial cost: The advanced technology and electronic components of ultrasonic meters make them more expensive to purchase than traditional mechanical meters.

Sensitivity to air bubbles: While some models use the Doppler effect to measure dirty water, the transit time method can be affected by a high concentration of air bubbles, which can scatter the sound waves and lead to inaccurate readings.

Power requirement: To function and transmit data, ultrasonic meters with smart features require a continuous power source, typically a long-life battery or a wired connection. This is a point of consideration during installation and long-term operation.

| Feature | Ultrasonic Water Meter | Mechanical Water Meter |

| Accuracy | Excellent; stable over time | Good; can degrade due to wear |

| Lifespan | Long (15-20+ years) | Shorter (10-15 years) |

| Initial Cost | Higher | Lower |

| Maintenance | Minimal; no moving parts | Regular; prone to wear |

| Flow Range | Wide | Narrower |

| Technology | Sound waves; no moving parts | Physical gears, turbines, or pistons |

| Features | Advanced, smart capabilities | Basic, simple measurement |

The choice between a mechanical and an ultrasonic water meter is often dictated by the specific application, considering factors like flow rate, water quality, and the need for advanced features.

Best Use Cases for Mechanical Water Meters

Residential Homes and Apartments: Mechanical meters are the traditional, cost-effective choice for individual households. Their low initial price and simple design make them ideal for large-scale deployments in residential areas. They are highly reliable for the low-to-medium flow rates typical of a single family home.

Small Commercial Buildings: Businesses with moderate and consistent water usage, such as small offices or retail stores, can benefit from the proven technology and affordability of mechanical meters.

Rural or Remote Areas: In locations where power supply for advanced electronics might be unreliable or nonexistent, the self-sufficient nature of mechanical meters makes them a practical solution.

Utility Infrastructure with Budget Constraints: For large-scale projects where initial capital expenditure is the primary concern, mechanical meters provide a reliable and low-cost option for basic water metering.

Best Use Cases for Ultrasonic Water Meters

Industrial and Large Commercial Facilities: Ultrasonic meters excel in environments with highly variable flow rates. Factories, hospitals, and large apartment complexes often experience both very low flows (e.g., a small leak) and very high flows (e.g., a sudden demand spike), which ultrasonic meters can accurately measure.

Smart City Initiatives: As part of a larger Internet of Things (IoT) network, ultrasonic meters provide the real-time data needed for smart water management. Their ability to send automated readings, detect leaks, and monitor consumption patterns is crucial for optimizing city-wide water distribution and conservation efforts.

High-Value or Critical Applications: In industries where water usage must be precisely monitored, such as chemical manufacturing or food processing, the superior accuracy of ultrasonic meters ensures accurate billing and process control.

Leak Detection and Water Conservation Programs: The sensitivity of ultrasonic meters to low flows makes them an invaluable tool for identifying small, persistent leaks that would otherwise go undetected by mechanical meters, thereby reducing non-revenue water loss for utilities.

Selecting the right water meter is a critical decision that goes beyond the initial purchase price. It requires a thorough evaluation of the specific application and long-term goals. Here are the key factors to consider:

1. Water Quality

The composition of the water is a primary determinant.

Clean Water: For residential and commercial applications with clean, potable water, both mechanical and ultrasonic meters are suitable. However, an ultrasonic meter will maintain its accuracy longer due to the absence of wear from minor particulates.

Dirty Water/Wastewater: For water containing sediment, debris, or air bubbles, a mechanical meter's moving parts can become clogged or damaged, leading to under-registration or failure. In these environments, an ultrasonic meter—particularly one using the Doppler effect method—is a more reliable and durable choice.

2. Flow Rate Requirements

The expected range of water flow is a crucial consideration.

Consistent, High Flow: For applications with consistently high flow rates, such as fire services or large industrial processes, velocity-based mechanical meters or large-diameter ultrasonic meters are appropriate.

Variable Flow: For applications with a wide range of flow rates, from a small trickle to a heavy surge, an ultrasonic meter is superior. Its ability to accurately measure very low flows is essential for detecting leaks and ensuring all water usage is captured for billing.

Minimum Flow Accuracy: This is a key parameter to compare. Ultrasonic meters typically have a much lower minimum flow detection threshold than mechanical meters, making them more effective at identifying small leaks and drips.

3. Budget

The financial considerations include not only the initial purchase but also the total cost of ownership over the meter's lifespan.

Initial Cost: Mechanical meters are significantly less expensive upfront, making them a more appealing option for projects with limited capital.

Long-Term Cost: When accounting for maintenance, potential revenue loss from inaccuracies, and the cost of eventual replacement, the total cost of ownership for an ultrasonic meter can be lower in the long run. Their longer lifespan and minimal maintenance requirements often offset the higher initial price.

4. Installation Environment

The physical location and surrounding conditions influence the type of meter that can be installed.

Space and Orientation: While mechanical meters often have specific installation requirements (e.g., a certain length of straight pipe before and after the meter), many ultrasonic meters have more flexible installation options, including the ability to be installed in any orientation.

Power Supply: Ultrasonic meters, especially those with advanced features, require a power source. Battery-powered models offer flexibility, but for data-heavy applications, a wired power source may be necessary, which can impact installation costs.

5. Long-Term Goals

The future vision for water management should be a part of the decision-making process.

Water Conservation: If a primary goal is to reduce water consumption and combat non-revenue water loss, the superior leak detection and data logging capabilities of ultrasonic meters are a huge advantage.

Smart Infrastructure: For utilities looking to build a modern, data-driven network, ultrasonic meters with IoT integration are a foundational component. They enable remote reading, automated billing, and a better understanding of water usage patterns.

| Parameter | Mechanical Water Meter | Ultrasonic Water Meter |

| Water Quality | Prone to damage from debris | Not affected by debris; sensitive to air bubbles |

| Flow Rate Range | Narrower; less accurate at low flows | Very wide; high accuracy across the range |

| Initial Cost | Lower | Higher |

| Maintenance | Higher; due to moving parts | Minimal; no moving parts |

| Total Cost of Ownership | Potentially higher (due to maintenance/replacement) | Often lower (due to longevity and no maintenance) |

| Leak Detection | Limited, especially for small leaks | Excellent, even for very low flows |

| Data Features | Basic, manual readings | Advanced, remote-reading, and analytics capabilities |

The water metering industry is in the midst of a significant transformation, driven by advancements in digital technology and a growing global focus on sustainability. The future of water meters is centered on intelligence, connectivity, and data-driven insights.

1. Smart Water Meters and IoT Integration

The most impactful trend is the widespread adoption of smart water meters, which are essentially ultrasonic meters equipped with communication modules. These meters are a key component of the Internet of Things (IoT), enabling a two-way flow of information between the meter and a utility's central management system.

Real-Time Data: Smart meters transmit consumption data automatically and frequently, eliminating the need for manual meter reading. This provides utilities with real-time insights into usage patterns, helping them manage resources more effectively.

Remote Management: IoT integration allows utilities to perform tasks like remote meter reading, service disconnections, and firmware updates without a physical visit. This dramatically reduces operational costs and improves efficiency.

Consumer Engagement: Through web portals or mobile apps, consumers can access their own real-time usage data. This transparency empowers them to monitor their consumption, identify inefficiencies, and actively participate in water conservation efforts.

2. Advancements in Ultrasonic Technology

Innovations in the core technology of ultrasonic meters are making them more capable, affordable, and accessible.

Improved Accuracy and Low-Flow Detection: Ongoing refinements in sensor and signal processing technology are enhancing the accuracy of ultrasonic meters, especially at extremely low flow rates. This allows for the detection of even the smallest leaks, a major step forward in combating non-revenue water.

Enhanced Battery Life: Manufacturers are developing more energy-efficient meters with longer-lasting batteries, with some models now offering a lifespan of 15 years or more. This reduces the frequency and cost of maintenance and replacement.

Miniaturization and Cost Reduction: As the components of ultrasonic meters become smaller and more economical to produce, their higher initial cost compared to mechanical meters is gradually decreasing, making them a viable option for a wider range of applications, including residential use on a larger scale.

3. Focus on Water Conservation and Leak Detection

With climate change and population growth putting pressure on global water supplies, conservation is a top priority.

AI-Driven Analytics: The vast amount of data collected by smart meters is being analyzed using artificial intelligence (AI) and machine learning. These algorithms can identify unusual consumption patterns that signal a leak, a burst pipe, or other anomalies, allowing utilities to respond proactively.

Proactive Maintenance: By analyzing historical data and usage trends, utilities can use predictive maintenance models to identify pipes or meters that are likely to fail, enabling them to make repairs before a major leak or outage occurs.

Non-Revenue Water (NRW) Reduction: Non-revenue water, which is water that is lost before it reaches the consumer, is a major issue for utilities. Smart meters with advanced leak detection and real-time data analysis are the most effective tools for reducing NRW and improving overall system efficiency.

| Parameter | Current Technology | Future Trends |

| Connectivity | Limited to AMR (Automated Meter Reading) or manual reads | Full IoT integration (NB-IoT, LoRaWAN) |

| Data Analysis | Basic data logging and manual analysis | AI-driven predictive analytics for leaks and maintenance |

| Battery Life | 10-15 years | 15+ years with improved efficiency |

| Cost | Higher initial cost for ultrasonic meters | Decreasing cost, making them more widely accessible |

| Functionality | Primarily for billing and consumption monitoring | Comprehensive asset management, leak detection, and conservation |

prevWhat mechanical wear problems are most likely to occur in large-caliber mechanical water meters during long-term operation

nextWhat are the common faults of wet water meters and how to troubleshoot them